Prosthetics and Orthotics System

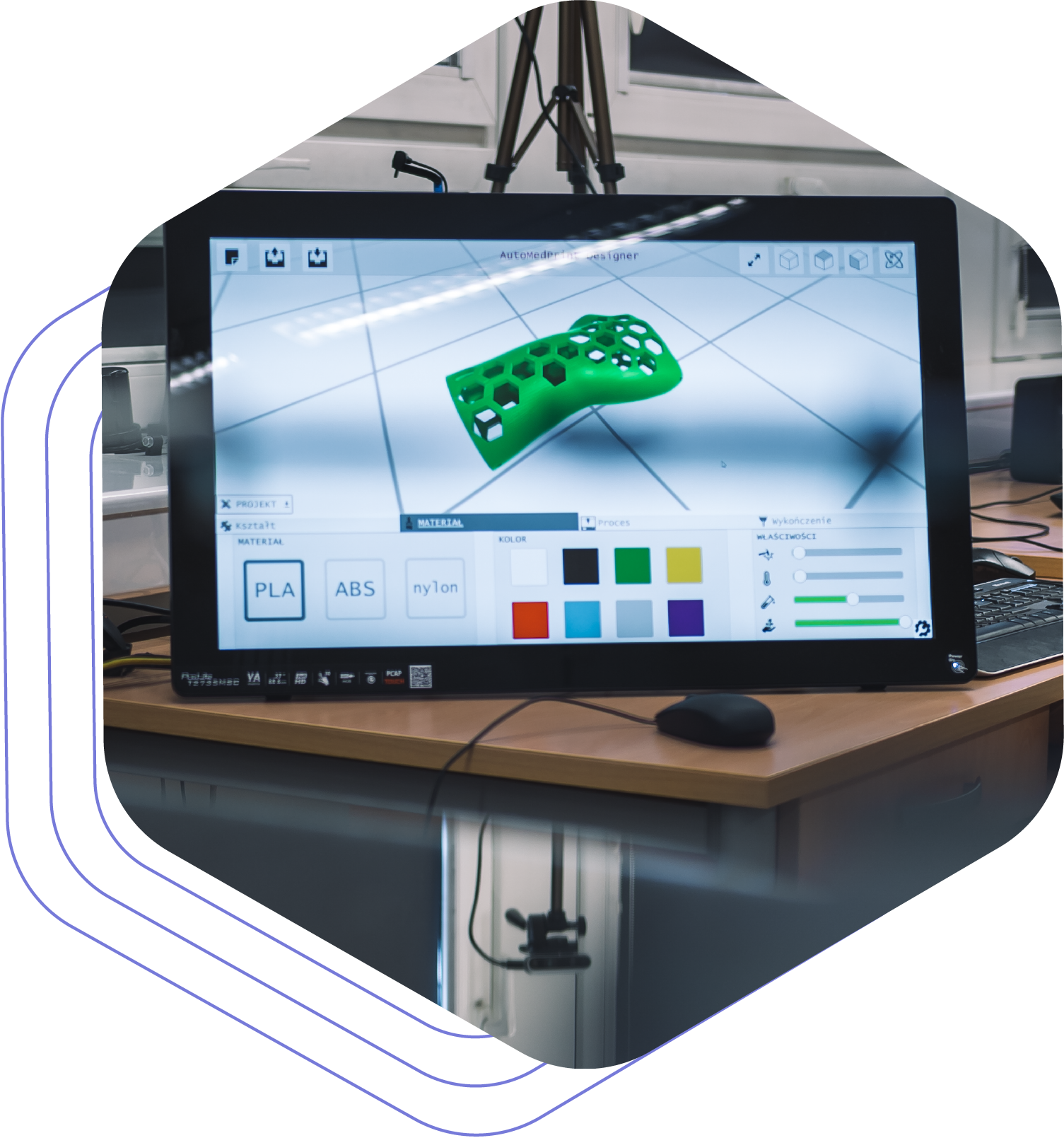

The prototype AutoMedPrint system developed at Poznań University of Technology is used for fast, automatic design and manufacturing of limb prostheses and orthoses using 3D printing, primarily for children. Our team—composed of mechanical and biomedical engineers—has worked in close collaboration with medical specialists to build a system that can deliver a functional prosthesis or orthosis even the day after measurements are taken. This is achieved using a 3D scanner within a specially designed workstation, at a fraction of the cost of traditionally manufactured equipment. This makes a huge difference for pediatric patients—most children with amputations or congenital deformities do not use prostheses due to their high cost, long lead times, and the uncomfortable, problematic production process.

Functionality and Availability

Our prostheses are fully personalized, and the use of simple artificial intelligence in the form of auto-generating 3D models allows for fast design and manufacturing without the need to involve a qualified engineer. As a result, the cost of a single prosthesis does not exceed 500 PLN. Ultimately, the AutoMedPrint system can be installed and used anywhere—in a hospital, clinic, prosthetic lab, or even a school—and only requires brief training to operate. This means it can be handled by medical personnel such as nurses, doctors, physiotherapists, or technicians. After a few minutes of 3D scanning the patient’s limb, the rest of the work is performed by a computer algorithm, which designs the device and prepares the program for the 3D printer. The entire solution is based on low-cost equipment, and the materials used for building the orthoses and prostheses are environmentally friendly.

Our Products

Our AutoMedPrint system is currently in the final stage of development. We have already completed most of the research and development work. The prototype is fully functional and enables the production of four different orthopedic devices: a wrist orthosis (used to treat fractures and injuries in the wrist and forearm area, as well as for hand therapy, e.g., in children with brachial plexus palsy), an ankle-foot orthosis (used in therapy for conditions such as cerebral palsy, spinal muscular atrophy, or post-injury stabilization), a cosmetic hand prosthesis, and several versions of a mechanical hand prosthesis (for general use and specialized applications such as cycling). All devices are manufactured using our own designs, and collaboration with orthopedic doctors and physiotherapists ensures their proper functionality. We have already helped many patients—our youngest was 1.5 years old, and there is no upper age limit. We are in advanced talks with local companies to commercialize the system, while also publishing the results of our research in high-impact international journals.

Stages of Prosthesis and Orthosis Production

Our orthoses and prostheses are created in several steps. Patients usually visit us 2 or 3 times—during the first visit, we perform a 3D scan, and a few days later, we deliver the finished device. If any adjustments are needed, we produce a revised version.

Thanks to automated design, our process is short, and with the use of budget 3D printers, our products are very inexpensive—this allows us to quickly create multiple prototypes and test different concepts.

Consultation

Watch Our Video

Listen to the team members and learn what the design process looks like behind the scenes

5 – 45

minutes

2 – 3

days

50 – 80

percent

Compared to

Current Methods

Priceless

Hand Orthosis

The WHO (Wrist Hand Orthosis) belongs to the group of orthopedic devices designed to stabilize the hand, wrist, and forearm. The personalized solutions offered within the AutoMedPrint project fully utilize the capabilities of 3D printing. Our orthoses feature a lightweight, openwork structure that enhances user comfort while also improving rehabilitation potential.

PERSONALIZATION

COMFORT AND AESTHETICS

PRODUCT CONFIGURATOR

MANUFACTURING

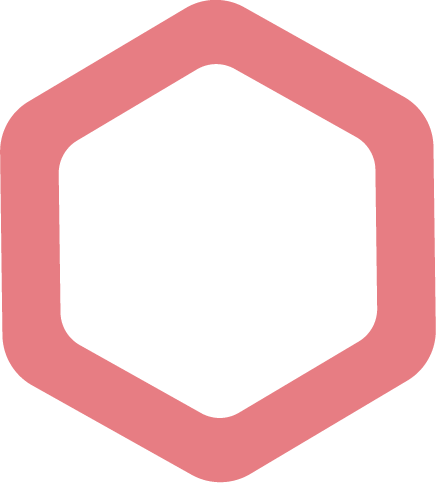

Cosmetic Hand Prosthesis

The cosmetic hand prostheses we offer consist of three components: the prosthetic socket, the forearm, and the prosthetic hand. Using the algorithms implemented in the AutoMedPrint system, measurements are collected contactlessly with a 3D scanner, and the acquired data allows for full personalization. This applies both to the prosthetic socket, which is adapted to the shape of the patient’s residual limb (regardless of the level of amputation), and to the other components.

DESIGN

MANUFACTURING

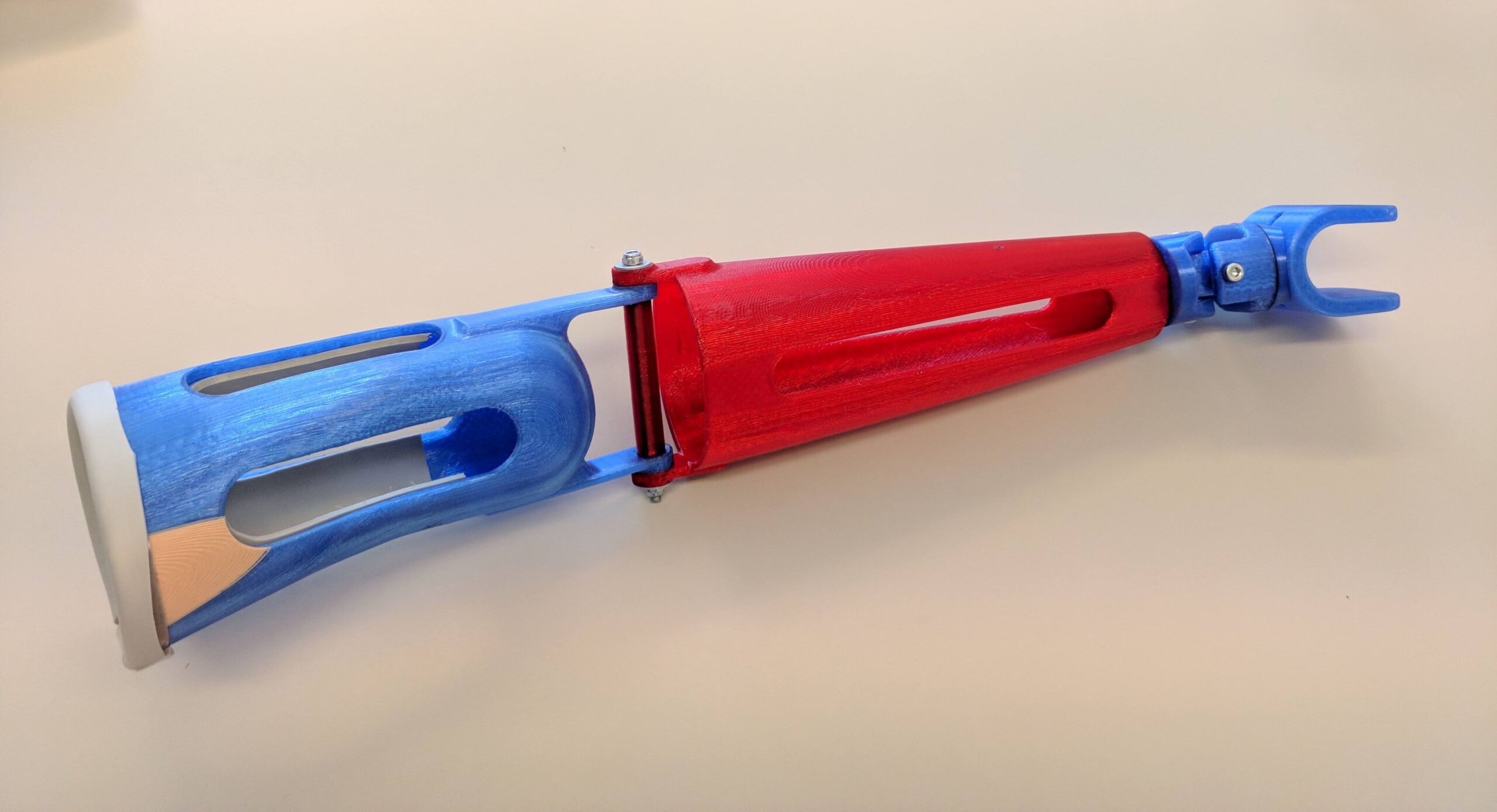

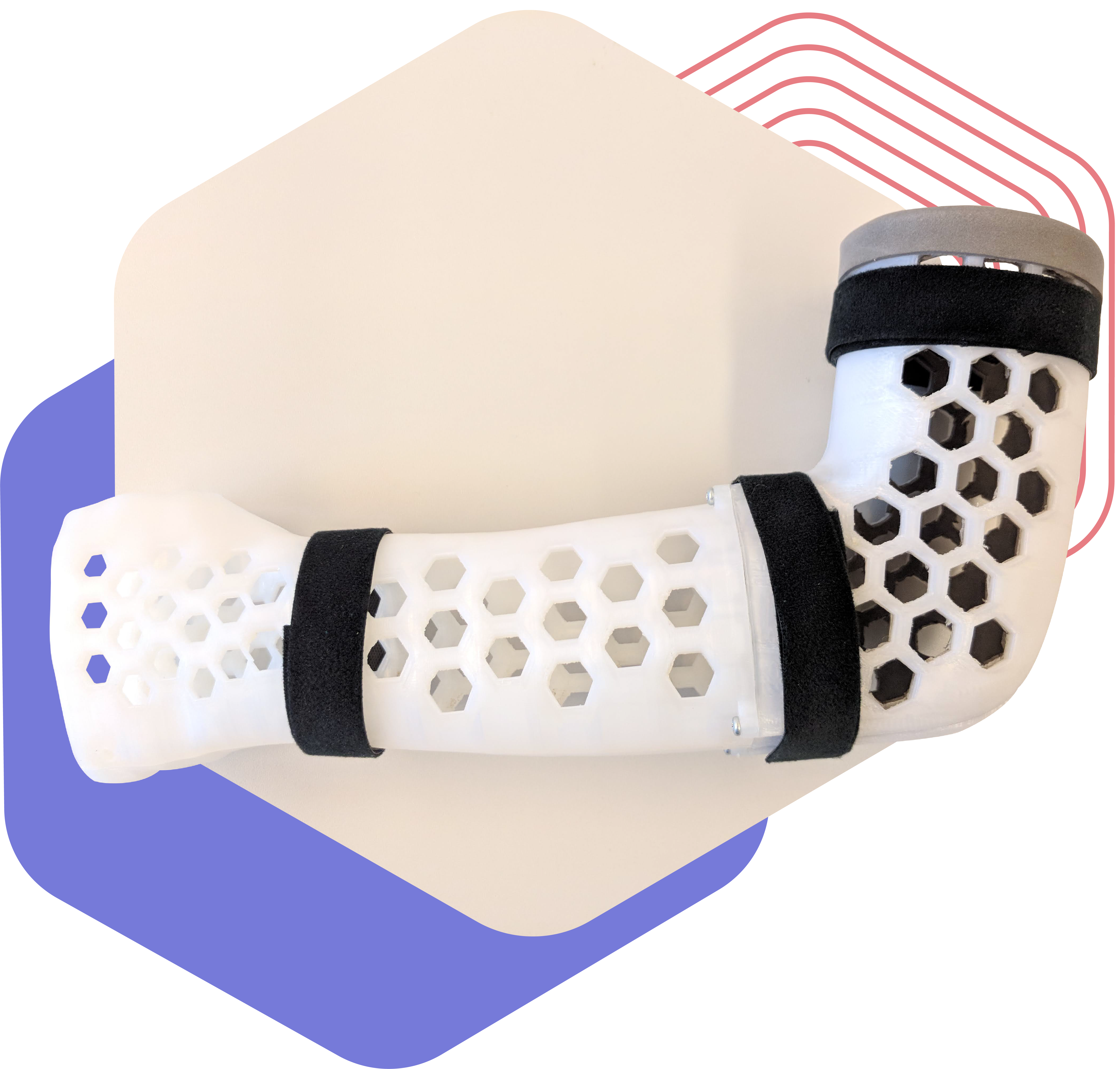

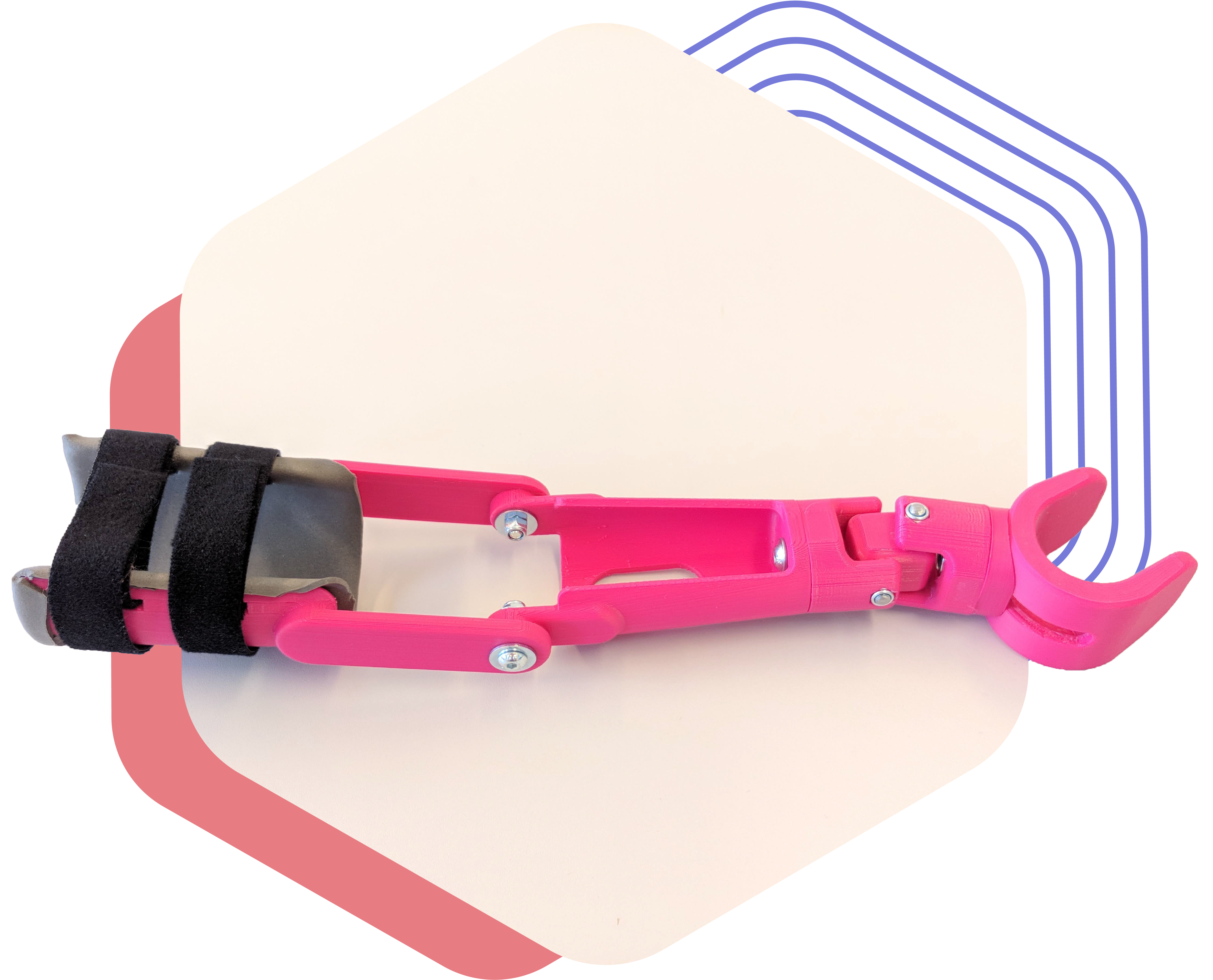

Functional Hand Prosthesis

The functional mechanical hand prostheses we offer include several solutions, depending on the user’s needs and anatomy. All prostheses are designed to support daily use, tailored to individual requirements. We create personalized prostheses for patients with virtually any type of limb loss—in the wrist, forearm, elbow, or upper arm area.

MECHANICAL PROSTHESIS

CYCLING PROSTHESIS

PERSONALIZATION

MANUFACTURING

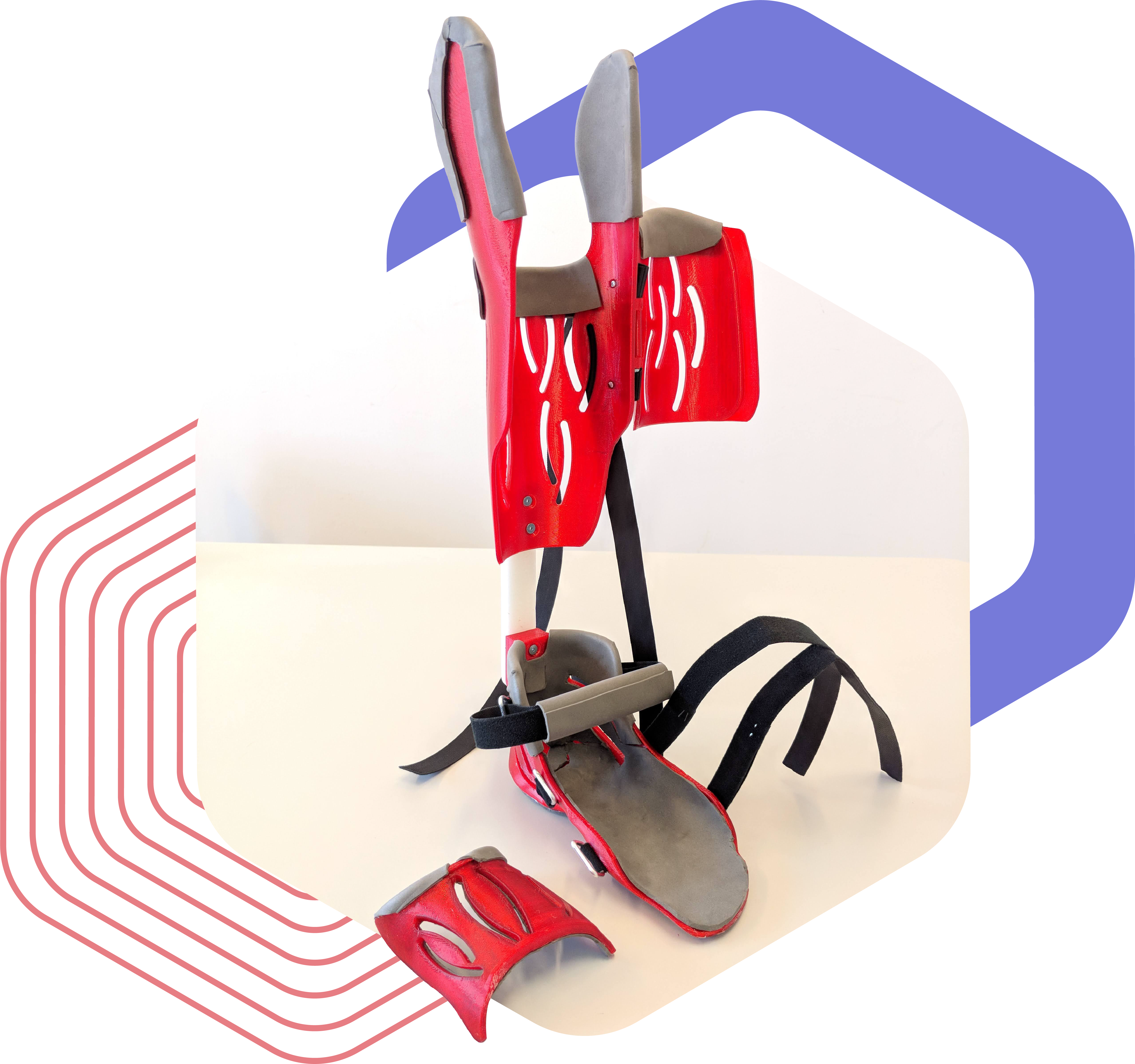

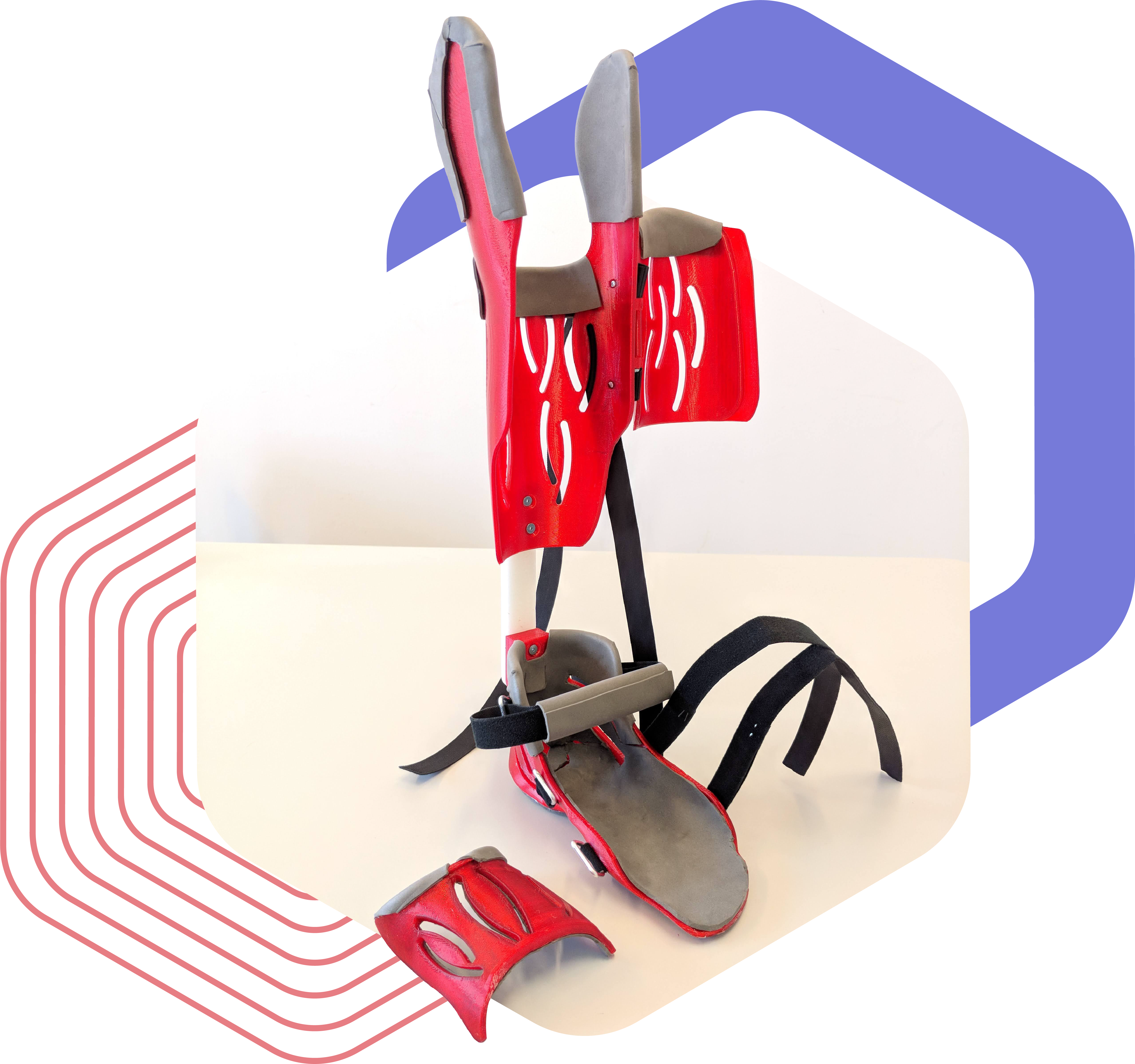

Ankle-Foot Orthosis

An AFO (Ankle Foot Orthosis) is designed to stabilize and correct the positioning of the foot, ankle joint, and lower leg. It supports the lower limb in maintaining gait stability and assists in rehabilitation by ensuring proper alignment during specific phases of walking. This type of orthosis can be used in rehabilitation for ankle joint instability or to correct deformities resulting from specific medical conditions.

PERSONALIZATION

SPECIALIZED ORTHOSES

MANUFACTURING

Unique Values of the Project

Automatic

Measurement

and Data Processing

Automatic Design

Product Design

Using a VR Configurator

Automatic

3D Printer

Programming

AutoMedPrint Patients

Janek

Stabilizing Hand Orthosis

Jan is an extremely active 9-year-old boy who always finds an opportunity to play. Unfortunately, one of those moments ended with a broken arm in two places, followed by surgery. This happened on the last day of school, with a vacation trip already planned. A traditional cast was out of the question. An unconventional solution was needed.

Using the AutoMedPrint system, a scan of the healthy hand was performed at the workstation, and the collected data were supplemented with an additional manual scan. Thanks to the obtained data and the natural symmetry of the human body, the orthosis was automatically designed and sent to print on the same day, i.e., the day of the first consultation. The next appointment involved minor adjustments, and the final product was delivered to Janek on the eve of his vacation.

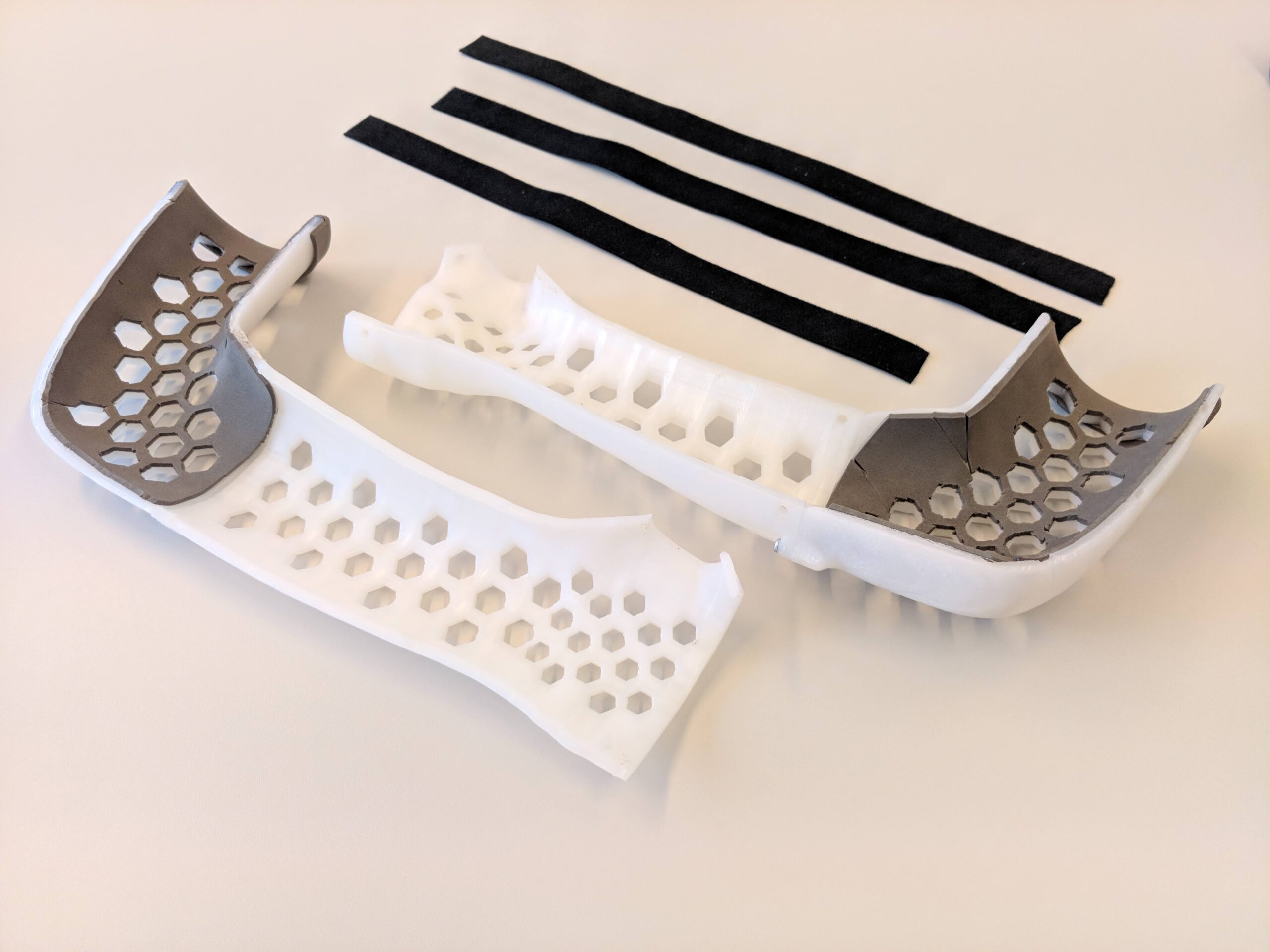

Two orthoses were provided, made from PLA (for daily activities) and nylon (for swimming). Both were lined with foam on the inside to enhance comfort. Additionally, the orthoses consisted of two stiffening parts: one dedicated to the wrist and the other to the elbow joint. Thanks to consultations with an orthopedic specialist and a physiotherapist, the model was designed so that it was possible to separate the orthosis and retain only the wrist part when maintaining the elbow position was no longer necessary.

Thanks to the AutoMedPrint system, it was possible to very quickly and automatically design and manufacture two functional orthoses, which proved useful in daily activities and allowed for a comfortable and healthy vacation.

A message from the family was a delightful finishing touch – our little patient swims, plays football, runs – and is tanned like no one else 😉

Zosia

Pediatric Mechanical and Cosmetic Prosthesis

Zosia is a cheerful 6-year-old girl who is always smiling. She was born without her left hand—she has only an upper arm stump (with no preserved joint). The daily activities of a young child often involve play that requires, among other things, balance. A dedicated prosthesis was needed, mainly for riding a bike. At the age of 3.5, Zosia was referred to our team by the e-Nable foundation and became our first patient—and an enthusiastic tester of new solutions ever since 🙂

Thanks to 3D printing, the cost of the prosthesis is significantly lower compared to commercial solutions, and regularly replacing components as the child grows is not a problem. The materials used, such as PLA, ABS, or nylon, maintain proper strength parameters, and there is always a current favorite color for our young patient in the color palette.

But that’s not all! Thanks to 3D scanning, it was also possible to create a cosmetic prosthesis, this time in natural skin tones, which is a 1:1 replica of the healthy hand. This allows Zosia, in addition to comfortable cycling with the mechanical prosthesis, to use the cosmetic prosthesis for daily activities such as walks or meeting with other children.

Zosia has been visiting us regularly for two years to update her existing devices. She is always cheerful and spirited, and each time she shows increasingly advanced cycling skills 🙂

Maciej

Mechanical Cycling Prosthesis – for Adults

The case of Mr. Maciej is one of the best examples of how powerful the Internet can be. A 40-year-old avid cyclist, he was born without his right hand (with a limb difference at the elbow joint). Since childhood, he has used various mechanical and cosmetic prostheses to support his daily activities. His experience in this field is unmatched—even among specialists.

As a result, his search focused on 3D printing technology and related hobbyist communities, which led him to us. Mr. Maciej’s prosthesis was generated based on a model for automatically creating children’s cycling prostheses, with appropriate scaling adjustments and consideration of different loads. Additionally, for Mr. Maciej’s prosthesis, a special compression-relaxation socket was used, automatically generated and tailored to the shape of the patient’s residual limb. The modern socket design allows the prosthesis to be used without additional straps, even under intense activity such as cycling.

3D printing enabled the creation of a properly balanced model, made from a high-strength material (PETG), and allowed the production of a compact prosthesis consisting of several interchangeable components, in case of misfit, damage, or discomfort during use.

Collaboration with Mr. Maciej provided valuable insights into the daily use of prostheses, and the AutoMedPrint system made it possible to produce a cycling prosthesis that met the patient’s requirements. Mr. Maciej continues to test additional experimental solutions for us.

Maja

Stabilizing and Rehabilitative Hand Orthosis

Who doesn’t love caticorns, right? Maja is definitely their biggest fan.

Six-year-old Maja was born with brachial plexus palsy, which significantly limits the use of her right hand and causes an improper wrist position. Despite the challenges, she never lacks the spirit to play and joke around.

Using data obtained from 3D scanning, it was possible to automatically produce a corrective orthosis, which, in addition to immobilizing and straightening the wrist, also serves a rehabilitative function. The area around the fingers is additionally freed, allowing the patient to perform basic grasping activities, engaging the entire hand while wearing the orthosis.

Thanks to the properties of 3D printing, orthoses of different weights could be produced, allowing the patient to choose the one most comfortable for her. In this way, at low cost and in a short time, Maja can wrap her Kotorożek plushie in a blanket while simultaneously rehabilitating her hand. 🙂

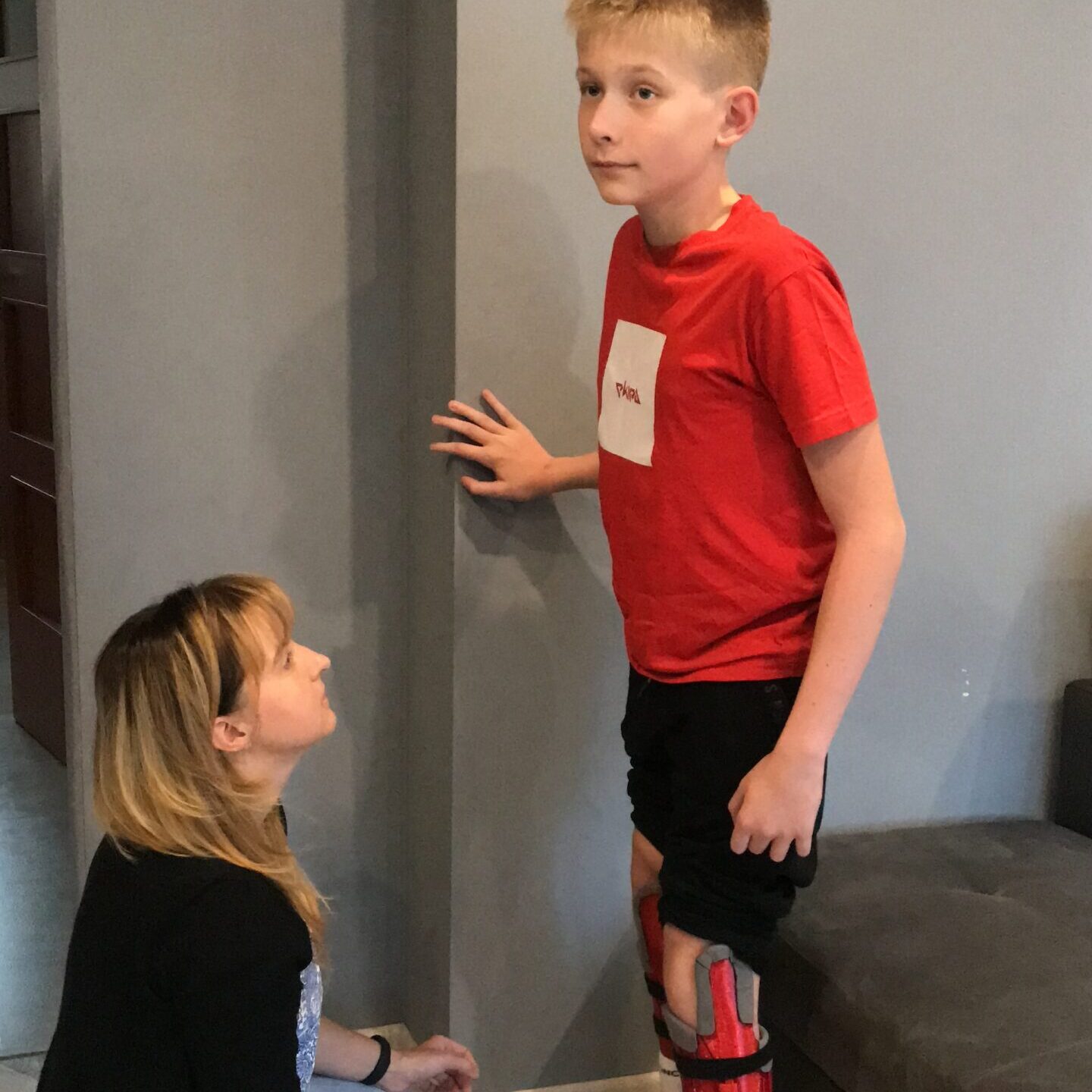

Miłosz

AFO Orthosis

Miłosz is a 13-year-old boy who, despite life’s challenges, continues to amaze doctors, physiotherapists, and those around him. Due to a spinal bifida in the lumbar region, he experiences paralysis of the lower limbs, resulting in flaccidity and a lack of sensation from the waist down. Additionally, one of his legs was shortened by 3 cm as a result of surgery. However, this hasn’t stopped Miłosz from staying active. Thanks to intensive rehabilitation and the dedication of both Miłosz and his parents, he is able to move independently using AFO orthoses.

Thanks to the AutoMedPrint leg scanning station, it was possible to generate orthoses tailored for the patient, equipped with additional elements to align the legs and provide knee support.

The 3D printing materials used, such as Nylon and PET-G, as well as the padding inside the orthosis, can withstand exposure to water. Moreover, the production cost of these orthoses is significantly lower than that of commercial solutions. All these factors resulted in functional orthoses for Miłosz, allowing him to continue his activities without any obstacles. 🙂

Are you a doctor?

Would you like to learn more or are you interested in collaboration?

Get in touch with us, and we’ll answer all your questions!

The research was funded by the National Centre for Research and Development – LIDER VIII program, contract no. LIDER/14/0078/L-8/16/NCBR/2017, project title: "Automation of Design and Rapid Production of Customized Orthopedic and Prosthetic Products Based on Anthropometric Measurement Data."

The award in the Polish Product of the Future Competition for “AutoMedPrint – an automated system for designing and 3D printing personalized limb orthoses and prostheses based on non-contact anthropometric measurement data” in the amount of PLN 100,000 was financed through Sub-measure 2.4.1 of the Intelligent Development Operational Programme (POIR), “Center for Analysis and Piloting of New Instruments inno_LAB.”